Material Actions in MWO

This section explains the distinctive features and functions supported in the Work Task Materials action. Below is a summary of the available features and functions, each of which is explained in detail afterwards.

- Required Materials

- Reserved Materials

- Issued Materials

- Receive Reserved Parts

- Issue All Reserved Parts

- Quick Issue Materials – from Stock

- Quick Issue Materials – from Spares

- Scan and Issue Materials

- Add New Material Demands

- Edit Material Demands

- Delete Material Demands

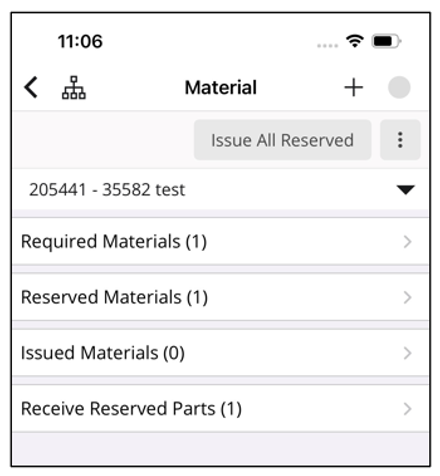

This is how the Materials page appears on the mobile client, showing users the relevant material information for their tasks.

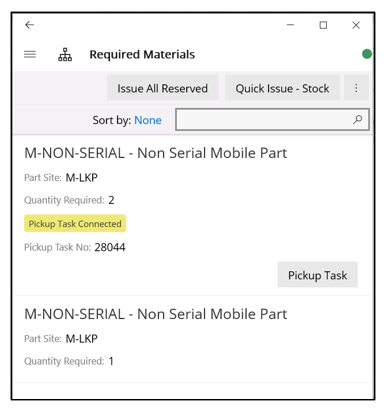

Required Materials

Under Required Materials, mobile users can view material demands associated with the work task. If the required

material is sourced externally, such as through a Purchase Order or Shipment Order, this information is displayed

on the material demand line, making it easy for mobile users to directly navigate to the source object to view

details and take actions.

These indications help mobile users understand the origin of the materials needed for their task.

Mobile users can also check stock availability directly from the demand line. If stock is insufficient, a Part Search can be initiated from the material demand to locate it in a nearby warehouse or from a technician.

Note: Part Search option is available only in the IFS MWO Service App.

Reserved Materials

In this section, mobile users can view the materials reserved for their task and see the warehouse where the material was originally reserved. Additionally, mobile users can use the Issue command to issue the reserved material once it becomes available (received in a warehouse the user has access to).

Issued Material

Materials already issued for the work are displayed in this section. Mobile users can use the Unissue command to return any excess material previously issued for the work task. The unissued materials will reappear in the Required Materials list if they need to be issued again, provided that the material line is not closed.

Receive Reserved Parts

The mobile user can view the work task material reservations that have not yet been received into the receiving warehouse (user warehouse) in this section. The mobile user must first receive the materials into the receiving warehouse (user warehouse) before issuing them against the work task.

Note: Refer to the document Stock Movement for further details.

Issue All Reserved

Mobile users can use this option to issue all reserved materials at once.

Quick Issue – Stock/Spares

During work execution, mobile users may encounter material requirements that were not originally planned. When the mobile user needs to issue a required part from the stock, they can use the Quick Issue option. This process creates the material demand and issues the part simultaneously.

- Quick Issue – Stock: This feature displays the current stock available to the user and allows them to issue parts. It also allows the use of Online Search to find and issue stock that is available to the user but not synchronized to the mobile device.

- Quick Issue – Spares: This feature displays the spare parts associated with the Equipment Object of the Work Task. It also allows the use of Online Search to find and issue stock that is available to the user but not synchronized to the mobile device.

Scan and Issue

Using Scan and Issue, the mobile user can easily scan the part's barcode, search for the required part in the available stock, and issue it. It also allows the use of Online Search to find and issue stock that is available to the user but not synchronized to the mobile device.

Add New Material Demand

Mobile users can use this option to create new material demands for the work task.

Edit Materials

The Edit option is available for material demands created in the mobile client (flagged as Added on Mobile) allowing the user to modify the Quantity Required and Required Date fields. However, editing is restricted if the mobile-added part demand has been processed further, such as when a shipment order is created in the back office. Additionally, editing is not available for serialized part demands.

Delete Materials

The Delete option is available for material demands created in the mobile client (flagged as Added on Mobile). However, deletion is not allowed if the mobile-added part demand has been further transacted. For example, partially issued part demands are not allowed to be deleted.