Stock Movement in MWO

This section explains various stock movement activities that mobile users can perform using the mobile application. These activities include,

- Replenishing van stock to fulfill material demands.

- Exchanging parts between the mobile user’s warehouses to fulfill ad-hoc material demands.

- Returning unwanted or unusable stock from the mobile user’s van stock to the central warehouse.

In the IFS Cloud Mobile solution, there are three main workflows for moving stock between warehouses:

- Planned standalone stock movement: To and from the mobile user’s own warehouse.

- Planned stock movement for reserved material demand: When a material demand for a task has been reserved from a central warehouse.

- Unplanned stock movement: To and from the mobile user’s own warehouse.

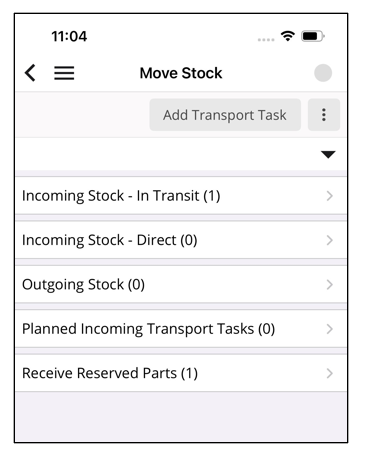

On the Move Stock page, these are displayed under the following categories:

- Incoming Stock – In Transit

- Incoming Stock – Direct

- Outgoing Stock

- Planned Incoming Transport Tasks

- Receive Reserved Parts

This is how it appears on the mobile client.

The planned stock movement workflows use Transport Tasks for moving stock between warehouses. The unplanned movements do not use Transport Tasks. Instead, the system registers the receipt of stock at the receiving end by scanning the QR code generated by the sender.

Planned Standalone Stock Movement Against Mobile User's Own Warehouse

The planned stock movement workflows use Transport Tasks for moving stock between warehouses. The unplanned movements do not use Transport Tasks. Instead, the system registers the receipt of stock at the receiving end by scanning the QR code generated by the sender.

Planned Standalone Stock Movement Against Mobile User's Own Warehouse

In this scenario, mobile users can:

- Execute a Transport Task for incoming stock (from a central warehouse or another mobile user’s warehouse to the own warehouse).

- Create and execute a Transport Task for outgoing stock (from own warehouse to a central warehouse or another mobile user’s warehouse).

Note: it is not possible to create a transport task to replenish your own stock from a central warehouse using the mobile app. This functionality is available only in IFS Cloud Web.

Planned Incoming Stock

The incoming stock move process explained below enables the mobile user to replenish his/her van stock in a timely manner so that the required material is readily available for his/her tasks. A prerequisite for this process is defining the user connection to the warehouse in the Maintenance/Basic Data/Users Connected to Warehouses page in IFS Cloud Web.

A transport task can either move the inventory immediately (e.g. you are picking up the material from the warehouse and placing it straight into the van. The inventory will move as soon as the transport task is executed. ) Or via transit (e.g. the parts are being transported/shipped to you, before you receive them physically and you will be able to see that they are in fact in transit) . The process is controlled by the Destination value on the transport task lines.

Incoming Stock – Direct

Here the list shows transport tasks with Destination set as Move to

Inventory. A planner can create a transport task in the back office, or another mobile user can create a

transport task from their mobile device to move stock directly from their warehouse. The transport task has the

To Location set to one of the receiver's connected warehouses.

The record is synchronized to the mobile user’s device from the back office with push Synchronization.

Note: if another mobile user creates the transport task from their mobile device, there may be a delay in areas of low connectivity, as the record must reach the server before it gets pushed to the receiver’s device.

Once the record is synchronized to the mobile user’s device, use the Execute action to receive the parts into the target warehouse and this removes the record from the list and updates the warehouse stock.

Incoming Stock – In Transit

This list shows transport tasks with the destination set as Move to

Transit. Once the sender executes the transport task, the next batch synchronization of the entity

InventoryPartInStock brings the in-transit record to the receiving mobile user’s device.

The receiving mobile user can then use the Receive All command to receive parts from transit into

his/her stock, and this removes the record from the Incoming Stock – In Transit list.

Incoming Stock when Destination Warehouse has a Drop-off Location

Here, executing a transport task with a drop-off location creates a new transport task between the drop-off location and the destination location. Once the record is synchronized to the mobile device, it updates either,

- Incoming Stock – Direct or

- Incoming Stock – In Transit list.

This is based on the value set for the Destination of the Transport Task. The receipt of incoming stock from this point onwards follows the same process as for incoming stock without a drop-off location.

Planned Outgoing Stock

This outgoing stock move process allows mobile users to move unwanted or unusable stock from his/her warehouse

to the central warehouse. Also, the mobile user can send the required parts to another mobile user’s

warehouse.

To perform this, use the Add Transport Task command on the Move Stock

page to create a Transport Task.

Note: When creating transport tasks from the mobile app, the application parameter DEFAULT_MOBILE_TT_DESTINATION controls whether the part is directly moved to the destination warehouse (MOVE_TO_INVENTORY) or if there is an in-transit step between the source and destination warehouse (MOVE_TO_TRANSIT).

Outgoing Stock

The Outgoing Stock list shows transport tasks that have not yet been executed. Use the Execute All command to execute the transport tasks from the sender's end. This removes the records from the Outgoing Stock list and reduces the quantity sent from the own stock.

- If the receiver is a central (non-remote) warehouse and the destination is set as Move to Inventory. The relevant stock gets updated once the record is synchronized to the back office.

- If the destination is set to Move to Transit, a warehouse worker must receive the parts from transit in the back office.

When a mobile user sends a part to another mobile user’s warehouse and executes the

transport task, the system synchronizes the information with the back office. As a result, the relevant Inventory

Parts in Stock record is updated on the server.

The next batch synchronization of the InventoryPartInStock entity brings these updates to the

receiver. Depending on the app parameter value for DEFAULT_MOBILE_TT_DESTINATION, the

receiver’s stock is updated directly or after the receiver completes the receipt from In-Transit.

Planned Incoming Transport Tasks

This list shows transport tasks that have not yet been executed and will be available for receipt in the future. It includes:

- Transport tasks in status Created with the Forward To location set to the mobile user’s warehouse.

- Transport tasks in status Created with the To Location set to the mobile user’s warehouse and Destination set to Move to Transit.

Note: This list is for mobile user information only and does not provide any action.

Planned Stock Movement for Reserved Material Demand

The planned stock movement process allows mobile users to receive parts reserved against their assigned tasks.

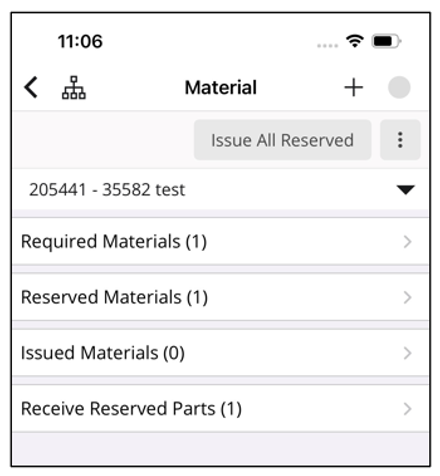

Receive Reserved Parts

This list shows transport tasks generated when a material demand for a task has been reserved from a central

warehouse. Mobile users can find Receive Reserved Parts records on both the Move

Stock page and the Work Details/Material page in the mobile client.

The destination of the transport task is set as Move to Inventory. Executing the transport task

moves the part to the mobile user’s remote warehouse.

This is how it appears on the mobile client.