Manufacturing Scheduling and Optimization (MSO) - Simulation Scenario

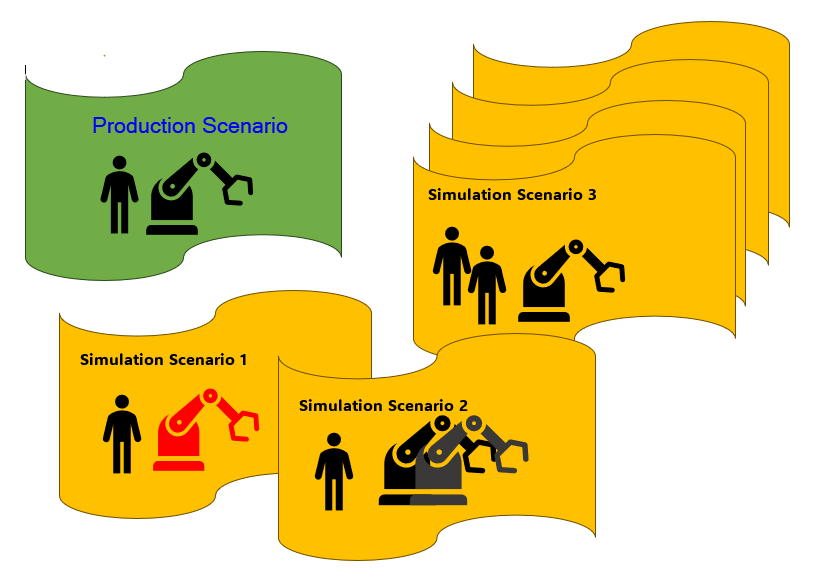

Simulation Scenario in Manufacturing Scheduling and Optimization (MSO) solution helps Manufacturers to do what-if scenario analysis and understand the advantages and disadvantage of different infrastructure schedules comparing actual production scenario versus different Simulation Scenarios.

The primary users of MSO Simulation Scenario are the Manufacturing planners and production managers. After simulation scenario analysis they can get required business decisions based on most productive infrastructure and do required modifications by understanding bottle-necks on the shop floor comparing on actual constraints/resources. Finally all stakeholders of Manufacturing facility can get the Benefit of higher productivity and feasibility on modified shop floor situation created based on Simulation Scenario in MSO.

Shop Floor Employees (i.e., Production Supervisors, Machine Operators, etc.) will also get indirect benefit of this with fully balanced work environment with manageable workload while consumers of manufacturing facility are getting the benefit of on-time order fulfillments from the IFS MSO using Manufacturer.

The Statistical Analysis or comparisons given on Simulation Scenario Analysis page helps Users to compare the Production scenario vs. simulation scenario based on different KPIs (Key Performance Indicators).

Figure 1 - MSO Simulation Scenarios

Setting up a new Simulation Scenario

Important: It is mandatory to have a 'Finite Schedule Basic Data' record for the Site to create a new Simulation Scenario for the same site. However activating the Production site dataset or creating a finite schedule for the base site is not mandatory. All Scheduling Rules and Optimization Goals on Simulation Scenario will be set based on the Production Site setup given in 'Finite Schedule Basic Data' page.

From Simulation Scenario page, MSO User can create a new simulation scenario and receive a simulated finite schedule for the Site. It is expected that User would use same scheduling rules and goals since those aspects are business specific parameters in production site as well as in the simulation scenarios of the base production site. Therefore the Rules and Goals like considering Operation Blocks, Setup Matrices,,..etc. given in Finite Scheduling Basic Data will be applicable for all simulation scenarios of the same site.

By default Minimum Acceptance Quality and Generate the scheduled within wait time will be set according to the base site, however the User can modify it for each and every simulation scenario by using the columns given in Dataset Parameters group. Simulation Dataset ID and simulation scenario Scheduled Date & Time also will be shown in Dataset Parameters group.

Capabilities of Simulation Scenarios

MSO Simulation Scenario functionality helps to get different variants of existing actual (base) production schedule,

-

By Modifying scheduling parameters of existing constraints and/or resources

-

By including and excluding existing constraints and/or resources

-

Or, by Adding new constraints and/or resources. etc.

- Once upon a new scheduling scenario header creation,

User will get a list of existing Work Center Resources of the Site in Work Center Resources Tab.

-

Then User can add desired hypothetical new resources into existing work centers or hypothetical new work centers.

-

Change/Add validity periods (i.e. Begin date and End Date) of Existing type or Added type Resources

-

Change Calendars of Existing type or Added type Resources. (Limited to already utilizing work time calendars on the site)

-

Change Finite Capacity to Infinite Capacity or Infinite Capacity to Finite Capacity

User will get a list of existing Labor Class Persons of the Site in Persons Tab.

-

Then User can add desired hypothetical new persons into existing labor classes or hypothetical new labor classes.

-

Change/Add validity periods (i.e. Begin date and End Date) of Existing type or Added type Persons

-

Change Calendars of Existing type or Added type Persons. (Limited to already utilizing work time calendars on the site. HR Schedule using persons will not be changed)

-

Change Finite Capacity to Infinite Capacity or Infinite Capacity to Finite Capacity

User will get a list of existing Labor Class Persons groups of the Site in Person Groups Tab.

-

Then User can add desired hypothetical new person groups into existing labor classes or hypothetical new labor classes.

-

Change/Add validity periods (i.e. Begin date and End Date) of Existing type or Added type Person groups

-

Change Calendars of Existing type or Added type person groups. (Limited to already utilizing work time calendars on the site)

-

Change Finite Capacity to Infinite Capacity or Infinite Capacity to Finite Capacity

User will get a list of existing Manufacturing tools of the Site in Person Groups Tab.

-

Then User can add desired hypothetical new tool instances into existing Tools or hypothetical new Tools.

-

Change/Add validity periods (i.e. Begin date and End Date) of Existing type or Added type Tools

-

Change Calendars of Existing type or Added type tools. (Limited to already utilizing work time calendars on the site)

-

Change Finite Capacity to Infinite Capacity or Infinite Capacity to Finite Capacity

Note: Only the Resources/Constraints with Planned, Released, Reserved or Started Manufacturing type Shop Order connections will be listed into Simulation Scenarios. All other resources or constraints that are not using in the production but required to consider for the scenario can be added manually as new resources or constraints.

2. 'Reset All Modifications' command of given in the Header to revert the modifications made into existing resources/constraints. This will not remove the Newly Added resources or constraints.

3. After creating the hypothetical situation on the Simulation scenario, User can Activate the Dataset by using the Activate Dataset command. After the Activation Scenario Owner will be set considering the User which Activated the Dataset. Only this User will able to edit or delete specific dataset same as in Finite Scheduling Basic Data page.

4. Then Schedule Scenario command can be used to make the schedule creation request to MSO scheduling service. Then the 'Not Scheduled' badge on header group will be disappeared and Latest Scheduled Start Time column will be appeared with the date and time information of the moment that simulation scenario actually start also considering the Scheduling Start Time (Hours) given in production Site setup given in 'Finite Schedule Basic Data' page.

5. After Scheduling of the Simulation Scenario, Scheduled Date Time column in Dataset parameters group will be updated with scheduled received time from scheduling service. After updating this date and time on Scheduled Date Time column, User will be able to see and analyze the results on Simulation Scenario Analysis page as well as the Simulation Resource Assignments page.