Prefabrication and Assembly

Once the detail designing of engineering assets is completed, these assets have to be built or prefabricated, and erected or assembled, physically in their respective facilities in order to carry out the rest of the life cycle processes such as operation and maintenance. Prefabrication is initiated via shop orders created on a design object and assembly is initiated via work orders created on a design object.

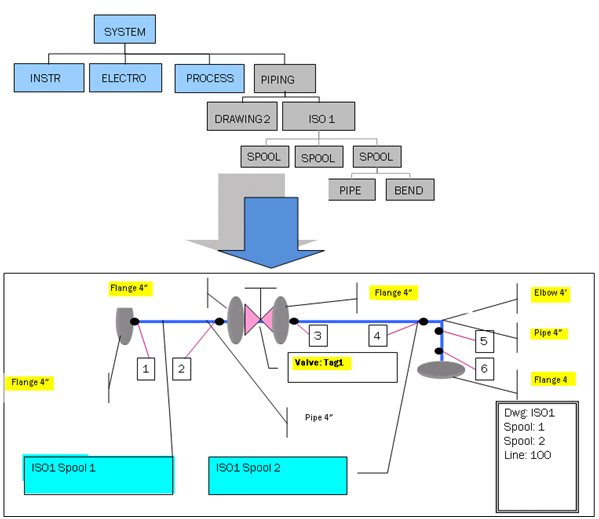

For an example, a pipe system (isometric) which is a part of a Mechanical Completion package might need to manufacture some of its pipe parts (spools) while the manufacturing process requires the purchase of some of the Bill of Materials. Prefabrication in this scenario, is easily and effectively handled by a direct integration between Asset Design, Manufacturing and Purchasing. More specifically a Shop Order and Purchase Order. Likewise, early prefabricated parts (spools) need to be assembled in order to complete the isometric and can then be erected. The integration to work orders is therefore useful at this instance, in carrying out all the assembly activities while receiving the planning, scheduling and reporting support.

The picture above shows an Asset Design Piping System (ISO1), consisting of many assembly parts (SPOOL1, SPOOL2 and SPOOL 3). Each of these assembling parts have to be prefabricated by using the material demand in the BOM (PIPE and BEND). In other words, ISO 1 is assembled by Spool 1 and Spool 2 and Spool 1 is prefabricated using Pipe Part, Equal T Square and Flange. At the completion of prefabrication, the required number of spools is received to carry out the assembling and complete the isometric.

Registering Demand Quantities and Types for a Design Object

It is very important to define the required material demand of the design object, including all additional parts, purchasing, fabrication and assembly quantities.

- The fabrication quantity is the quantity required for shop orders

- The assembly quantity is the quantity required for work orders

- The supply type is the method for acquiring the additional part. Possible values are Project Inventory and Invent Order. The default value selection depends on the existence of a valid project connection. It is possible to swap between these at any given moment. If the design object has a valid project connection, all demand lines by default receive the Project Inventory type. If no project connection exists, all demand lines receive the Inventory Order type.

- The fabrication type is how the material will be manufactured using the shop order. For example, Weld. When a shop order is created on a design object (spool), it is possible to select the required fabrication type. The resulting shop will then only consist of the materials that are of the respective fabrication type. By doing so, it is possible to create multiple shop orders on the same design object with different prefabrication and material requirements/types.

Prefabrication

This process involves identifying the assembling parts (spools) of a design object and registering the prefabrication demands (defined in BOM) either in manufacturing or purchasing depending on the supply options. For example, consider an isometric object of two spools (Spool-1 & Spool-2). The demands of each spool are handled and then prefabricated as a single unit via a shop order and purchase order. These prefabricated units are then readily available for assembling activities.

Creating Design Parts and Enabling Shop Order

Most of the isometrics, spools and design objects which are imported from third party design tools might not have a design part connected. So It might not be possible to create shop orders on these isometrics unless a design part is manually connected to a design object. So it is possible to create and connect a design part with a part number to the design object to be manufactured. The design part ID and part number are the same as the design object ID, by default.

Creating an Assembly Structure for a Design Object

Prefabricated parts (spools) might need to be assembled in order to complete an isometric design object. In such cases an assembly structure, comprising of objects with connected design parts and part numbers can be defined for an isometric design object. The design parts of the objects defined in the structure could be enabled to become the material demands of the assembly parent when work orders are created for the assembly parent.

Assembly

Assembly is the next phase of an isometric object which has gone through both the design and prefabrication phases. This involves assembling a design object combining all of its assembling parts (spools) on the facility. This could either be carried out by an in-house team or by an external party. Due to the complexity and the workload it is easier to create a work order from the design object while transferring the required materials and operations. A completion management activity has to be considered as the next step of assembly.

The picture below shows an assembly structure to be made, and is followed by a list of the potential scenarios for which the assembly should be carried out and how work orders can be created in order to do so:

In Scenario 1, three spools have been received into inventory either

as prefabricated material or as purchased material, and the isometric object

(ISO1) needs to be assembled by combining Spool 1, Spool 2 and Spool 3. In order

to do so, a work order can be created on the isometric object (ISO1) including

Spool 1,2 and 3 as the main material requirement.

In Scenario 2, the

material demands are received into inventory via Receive Inventory or Receive

Purchased Order, and Spool 3 needs to be erected by combining pipe and bend.

In order to do so, a work order can be created for spool 3 including bend and

pipe as the main material requirement.

Therefore depending on the nature

of assembly, IFS/Asset Design supports the creation of work orders for either

ISO 1, Spool 3 or both ISO 1 and Spool 3, to handle the main material requirement

of the assembly work.

Design Object Work Preparation

Design Object Work Preparation page considers as the main place to prepare and view work information for a particular design object. This includes design part and project connection information for the design object, assembly structure along with the list of additional parts for the design object.

The additional parts defined here, can be supplied with the information related to work preparation, such as such as fabrication type and quantity, assembly type and quantity, and supply type. The additional parts defined here, will be available to become the materials used in shop orders and work orders, provided the fabrication quantities and assembly quantities of the additional parts are greater than zero respectively. Similarly, additional parts could be included or excluded as material requirements of a shop order or work order based on the fabrication type and assembly type values specified when creating the shop order or work order respectively. For example, an additional part will become the material of a shop order if its fabrication type is the same as the type requested by the shop order. In addition, the supply type, Project Inventory or Invent To Order, directs the location from which these additional parts defined as materials could be received when the real work starts

It can also be used to initiate fabrication and assembly activities

such as creating shop orders and work orders, via the respective command button

options. The information about the created shop orders and work orders are also

displayed on the respective tabs, from where it is possible to navigate to and

view more details about these orders. You can also create an assembly structure

for a particular design object using the relevant tab on this window.

Optionally, you can create and connect a design part in inventory of

the default type, manufactured part, to a design object, and connect a design

object to a project and activity by using the respective command button options.

In doing so, the option to create shop orders can be enabled for the design

object. This option is useful for design objects (isometrics) that are not initially

connected to a design part, especially when they are imported from a different

design too Prefabricated parts (spools) might need to be assembled.